Another recommendation is that the maximum slab aspect ratio length to width should be 1 5 1 in order to minimize the possibility of transverse cracks.

Fibre distribution in macro plastic fibre reinforced concrete slab panels.

Sikafiber force 600 is a macro synthetic fiber designed for maximum performance in shotcrete application and as a replacement for welded wire mesh wwm in a wide range of concrete applications from industrial slabs on grade to precast structures.

Cost and environmental benefits and applications of fibre reinforced concrete are discussed.

For 4 to 6 inch thick slabs aci recommends joint spacings from 8 to 15 feet for somewhat square slab panels based on a number of factors such as concrete shrinkage potential.

De la fuente a.

The result is crack control and an extended service life of the concrete synthetic macrofibers are manufactured from a proprietary blend of polypropylene resins in compliance with astm c 1116 c 1116m.

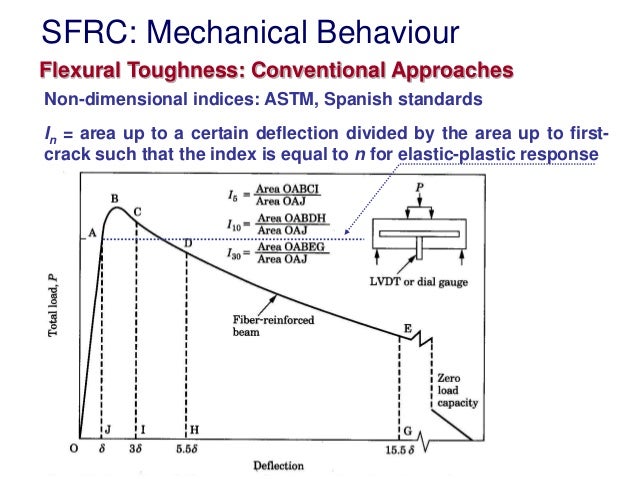

Macro plastic fibre reinforced concretes show excellent post cracking performance.

2014 fibre distribution in macro plastic fibre reinforced concrete slab panels pdf 2 104mb accés restringit sol licita una còpia a l autor.

Aguadofibre distribution in macro plastic fibre reinforced concrete slab panels constr build mater 64 2014 pp.

This composite has proven to be a competitive material in many types of structures in several of them fibres are used for structural purposes substituting partially or completely the conventional reinforcement.

Sikafiber force 600 meets the material specifications of astm c 1116 type iii fiber.

Biddle says dosage rates of macro fibers between 3 to 7 1 2 pounds per cubic yard of concrete produce slabs with reduced shrinkage and curling.

These unique fibers add superior bonding properties to the concrete matrix.

The side walls slightly redistribute the fibre orientation as the transverse dimension of the slabs is reduced.

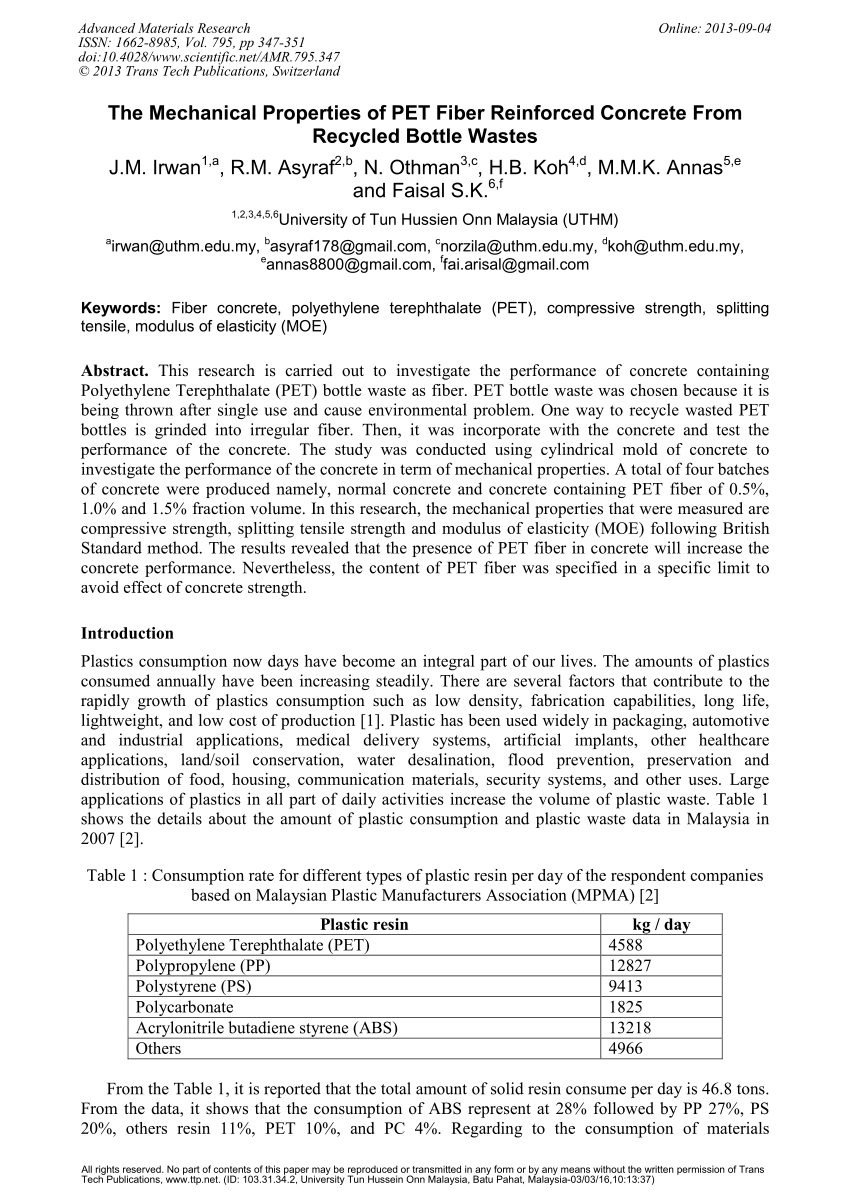

The fibers for micro products are made primarily from nylon or polypropylene each having the same effect on concrete while macro fibers are typically made of polypropylene and related co polymers.

Fibre reinforced concrete frc is one of the most relevant innovations in the field of special concretes.

The addition of fibres provides enhanced.